Waste plastic, a more common kind of recyclable material, recycling process will be selected according to different material conditions, encounter complex mixed broken material, etc., will use this process of sorting, plastic sorting is commonly used by the use of machinery and equipment for sorting, before there is a manual sorting way, However, it is obvious that this method can not meet the requirements of separation demand and efficiency, so it has almost been eliminated, only occasionally to assist the machine sorting, or a small part of the recycling process of easily recycled materials.

The use of mechanical sorting, higher purity, higher efficiency, lower cost

Plastic recycling is to pay attention to the cleanliness of plastic, that is, the degree of purification of waste plastic materials. After all, plastic with single material and no debris is more suitable for the next step of recycling and reconstruction, and the value of such plastic is also higher. The use of plastic sorting machine, is to solve the problem of impurities in plastic, to help the recycling of plastic manufacturers to obtain good recycling income.

For example, refrigerator, air conditioning and other household appliances shell broken material, although the plastic content is high, but also because it contains some silicone and metal, or broken and stacked when the debris contaminated the price, want to obtain the ideal income, it is necessary to separate the plastic in these broken materials.

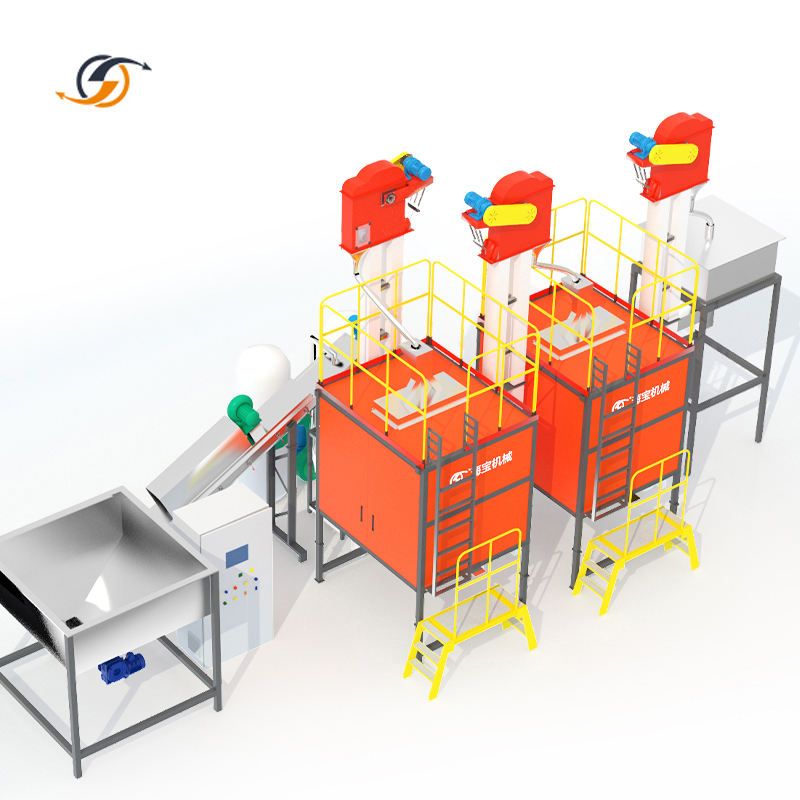

Sorting plastic debris in the machine called “silicone machine”, it can remove the plastic in silicone, rubber, wood chips, debris, dust and other things, very suitable for daily necessities of broken material plastic recycling, before the silicone machine, will go through the drift tank treatment, can initially distinguish the material of plastic, recycle the metal, remove stones and other heavy objects.

Send your message to us:

Post time: May-04-2024