At present, the separation technology for waste plastics mainly includes manual sorting, density separation, flotation, magnetic separation, electrostatic separation and so on.

Manual sorting is the original sorting method, but it is time-consuming, laborious and low efficiency. It is only suitable for some impurities that are easy to be found and sorted out.

Density separation is a method to classify different plastics with different densities. There are two methods: static separation and spin-liquid separation. It is suitable for the separation of varieties with large density difference, but it is difficult to obtain high purity of the separation of similar density.

Flotation is a technology that uses different specific gravity of substances in solution medium for sorting. The limitation is that the density of dissolved medium is difficult to control, which will pollute water to a certain extent, but also produce adverse by-products, and sludge needs follow-up treatment.

Magnetic separation is a technology that uses the magnetic difference of various materials to separate under the action of magnetic force and other forces, including eddy current separation. Eddy current is the use of magnet alternating magnetic field on metal induced electromotive force to drive metal accelerated movement from non-metallic materials, is widely used in metal separation field, or for non-ferrous metal and plastic material separation. The limitation is that there is no sorting power for non-metallic materials.

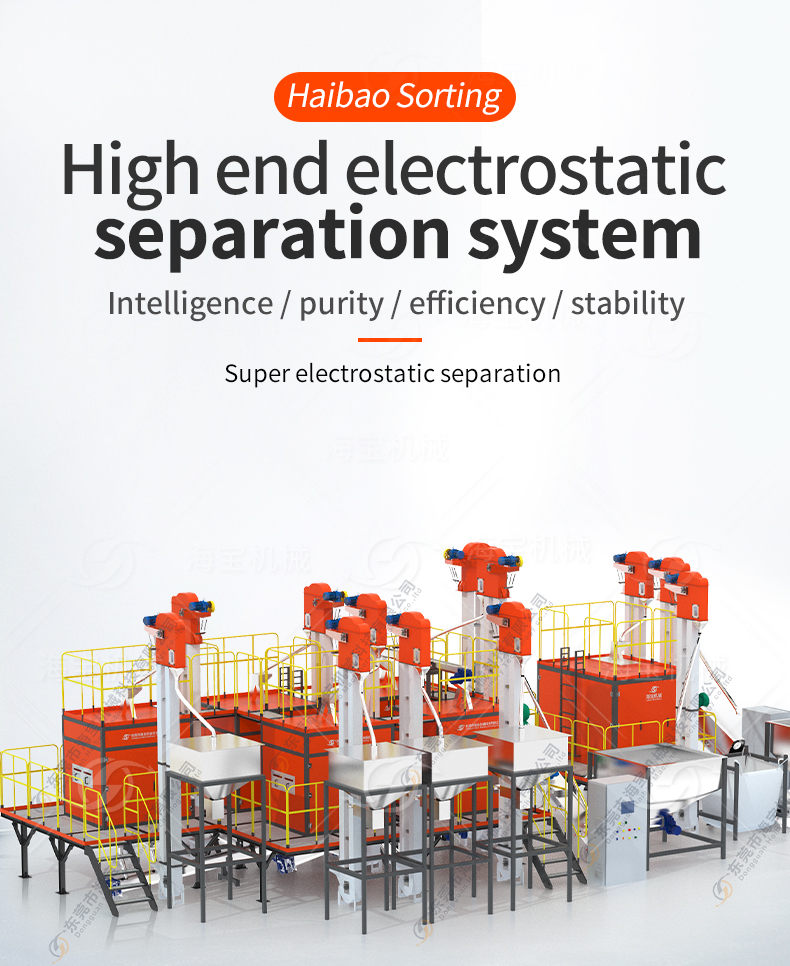

Electrostatic separation is the use of various plastics conductivity and electric field acting on the electrostatic properties of plastics to carry out separation. The use of electrostatic separation, plastic electrostatic separator will generally be used to separate 2-5 kinds of different types of mixed plastic broken materials through electrostatic means, for a variety of mixed together waste plastics need to be sorted several times. The use of plastic electrostatic separator, sorting speed is fast, up to 1-3 tons/hour, 20mm below the crushing material single sorting purity can reach 95% or more, simple operation, 1 person can complete the operation time and labor saving.

Send your message to us:

Post time: May-06-2024